Case Study by the department of Food Protection Systems at Plant-Ex ingredients on Carmine replacements.

Currently, Carmine blends are used to provide the pink colour in seasonings which are then used in meat products. Carmine is not a clean label colouring foodstuffs, therefore it presents challenges with consumer perception and familiarity, which in turn can be problematic for producers and manufacturers due to an increasing shift in the number of consumers seeking transparent, familiar ingredients within their food products.

Alongside this, carmine is manufactured from the cochineal beetle, it takes 70,000 female beetles to produce around 1 pound of carmine pigment, and sustainability questions are raised. Gebhardt et al (2020) concluded that carmine is not as sustainable as anthocyanins, therefore, with an increasing focus from the consumer on sustainability and transparency surrounding food ingredients, replacing carmine is an important challenge that must be undertaken.

Aim of the study:

The aim of this project will be to suitably identify a replacement for carmine which is commonly used within the food industry to enhance the pigments in meat.

Challenges of the project:

•Identify the correct dosage of alternative colouring foodstuffs that can be used in a similar way.

•Other factors impacting pigmentation degradation –ie; fats within meat causing rancidity.

•Flavour impact from additives.

•Colour change observed when cooking.

Methodology:

Whole cuts of beef obtained from a local butcher with a 10% fat content are minced using a meat grinder, and 5% breadcrumbs are added to the total weight of the mix alongside 4% salt and pepper (14:86) this is thoroughly combined and is a mixture created to replicate that of shop bought, chilled burger patties, minceis then dosed with colour and put back through the meat grinder to help with dispersal of additive. Minceis was then placed into petri dishes and vacuum-sealed to replicate packaged burger products.

Phase 1:

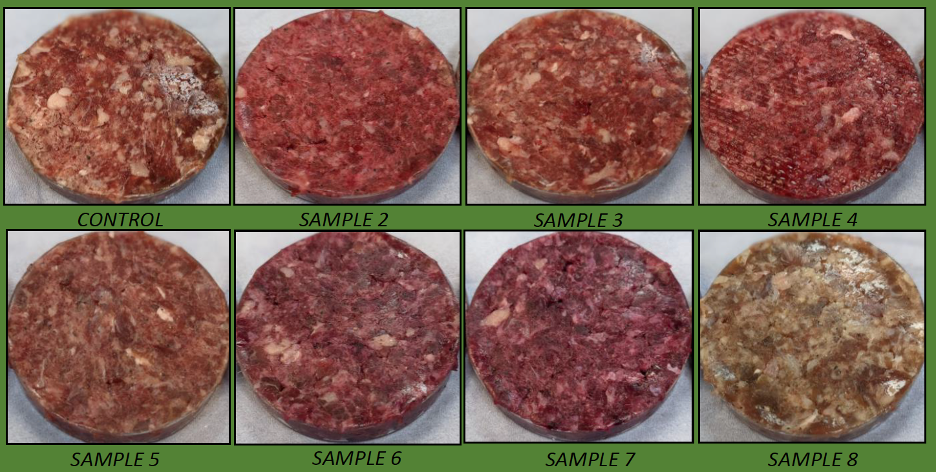

Samples are made as follows:

Day 0:

Control: mincemeat no added colours or AO’s.

Sample 2 -NC1207 –Carmine @ 0.05% mincemeat

Sample 3 -NC1204 –Carmine @ 0.1% mincemeat

Sample 4 -CF016253A –RED BEET HS @ 1% mincemeat

Sample 5 -CF013447A –BURGER RED POWDER @ 1% mincemeat

Sample 6 -CF014450A –RADISH POWDER @ 0.5% mincemeat

Sample 7 -CF019666A –RADISH POWDER @1% mincemeat

Sample 8-FPS019966A–GT OS @0.75% mincemeat

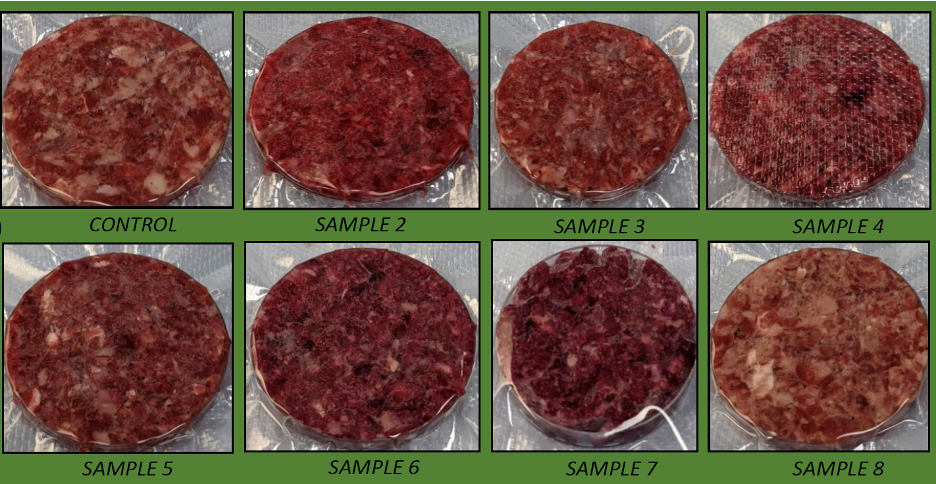

Results – VISUAL ANALYSIS

Day 0

Samples, when they were first made, are shown here, these are the standards that were set on the X rite machine. Dosing the meat with colour can add value to the product, making it appear to contain more flesh/ red meat than fat. Rich gamey colours can also be observed.

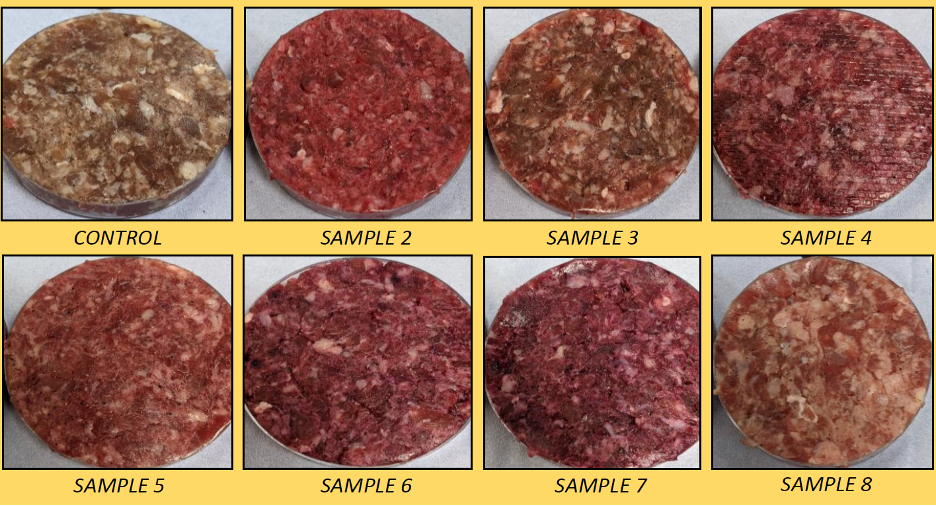

Day 1

Samples after 1 day, vacuum sealed and in chilled storage of 3 o C. Notice that all samples have slightly lost colour, this is due to photo-oxidation between the meat pigments and fat, this can be prevented with antioxidants that will delay the onset of photo-oxidation, see Sample 8 which is an antioxidant.

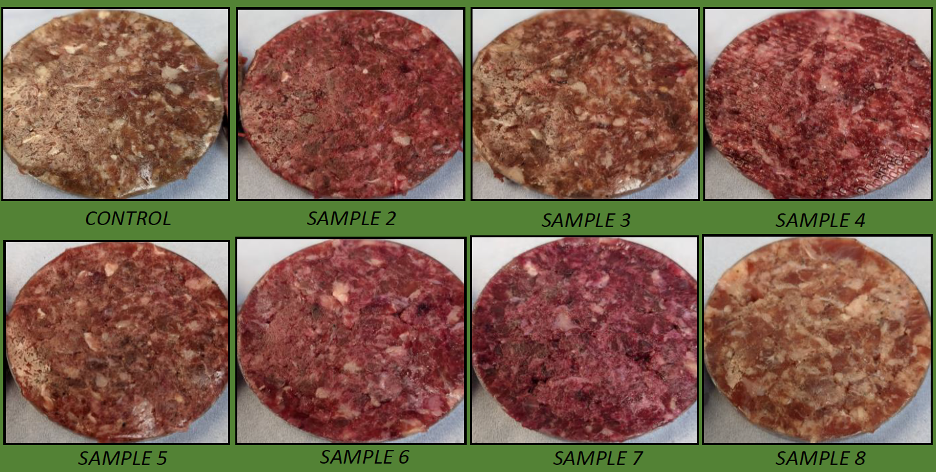

Day 2

Samples have shown prominent signs of fading, compared to the control sample, all samples

whilst faded, have maintained the colour in the meat. Sample 8 has again retained the natural

colour of the meat.

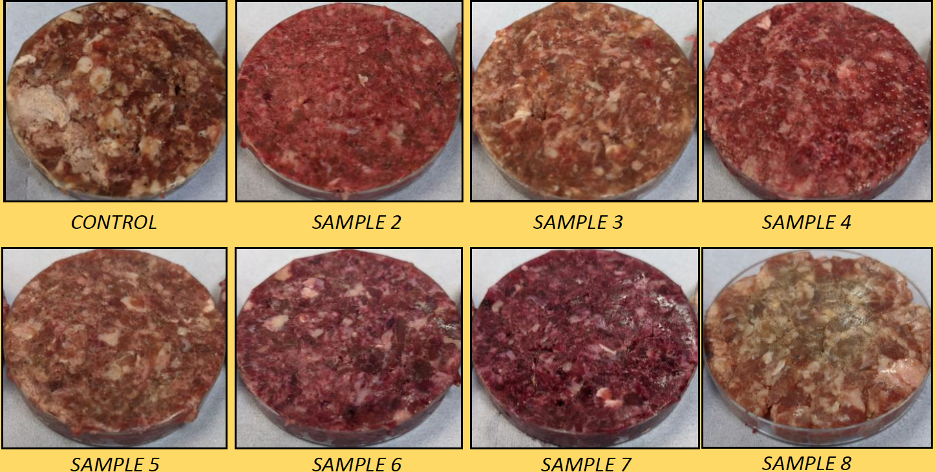

Day 3

Samples are fading and losing colour strength and this is more prominent, the control sample is showing strong signs of photo-oxidation. Sample 7 is showing strong colour retention compared to the other samples.

Day 4

The samples have really shown signs of oxidation and the colour change is most noticeable here, some samples have started to develop colours similar to how they were at day 0. This can be caused by the myoglobin in the meat undergoing chemical changes.

VISUAL ANALYSIS- CONCLUSION

The visual analysis has identified Samples 4,7 and 8 as potential candidates to replace carmine in a processed meat application, this is due to the colour being retained in these samples throughout the duration of the study and appearing to fade the least. Sample 8 has shown good capabilities in preventing photo-oxidation of the meat pigments, and a stronger dosage may provide increased efficacy.

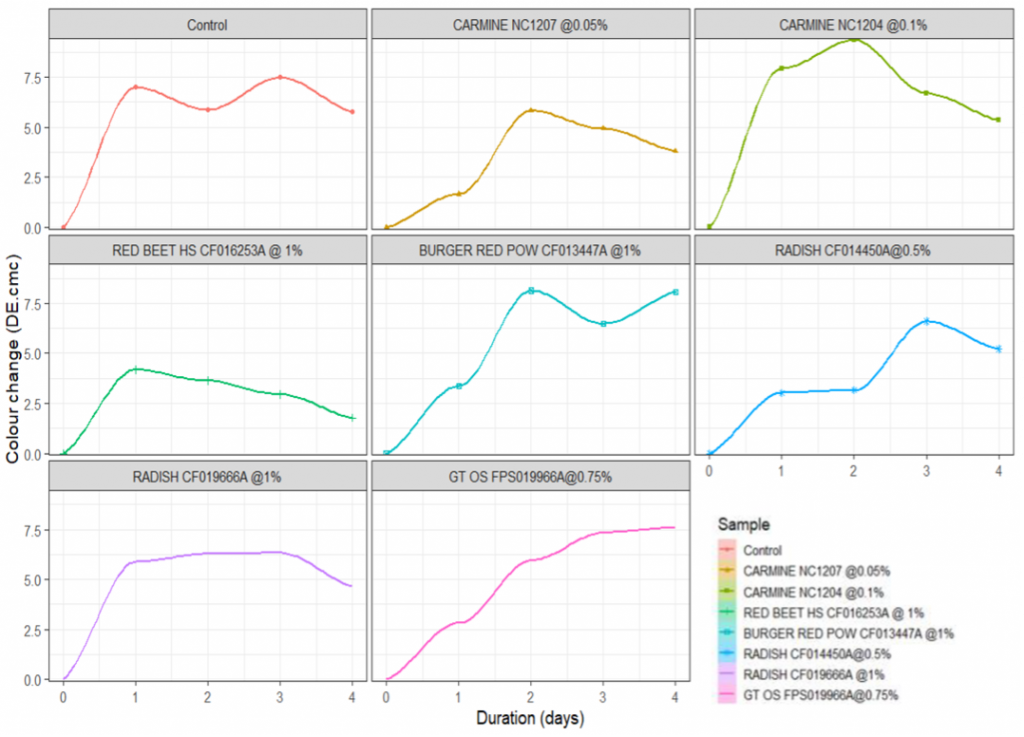

RESULTS- X RITE ANALYSIS

The X rite analysis shows that Red beet HS @1% has maintained a relatively stable colour change when dosed into minced beef, Radish CF019666A@1% has also shown relatively stable results. GT OS has not shown stability on the x rite, however, visual analysis has shown efficacy.

CONCLUSION

Samples 4 (Red beet HS) 7 (Radish CF019666A) and 8 (GT OS) have shown good

stability in meat application, these samples will progress to secondary testing where

correct dosages will be identified and the addition of antioxidants to help protect the

pigments will be added.

For a more in-depth analysis, our Food Protection Systems team has worked on the 2nd phase of this study

PHASE 2 TESTING

The results obtained in Phase 1 of the investigation identified several candidates to replace carmine in processed meat products.

Phase 2 testing is a repeat of the first test using the samples identified as being suitable replacements. Samples were made as follows:

Control 1 –Minced meat – No AO added

Control 2 –NC1207 Carmine @ 0.1% – mincedmeat

Control 3 –NC1207 Carmine @0.03% – mincedmeat

Sample 1-CF016253A –RED BEET HS @ 0.5% – mincemeat

Sample 2 -CF016253A –RED BEET HS @ 0.3% – mincemeat

Sample 3 -CF019666A –RADISH POWDER @ 0.3% – mincemeat

Sample 4 -CF019666A –RADISH POWDER @0.15% – mincemeat

Sample 5 -FPS019966A –GT OS @1% – mincemeat

Sample 6 -FPS019966A –GT OS @2% – mincemeat

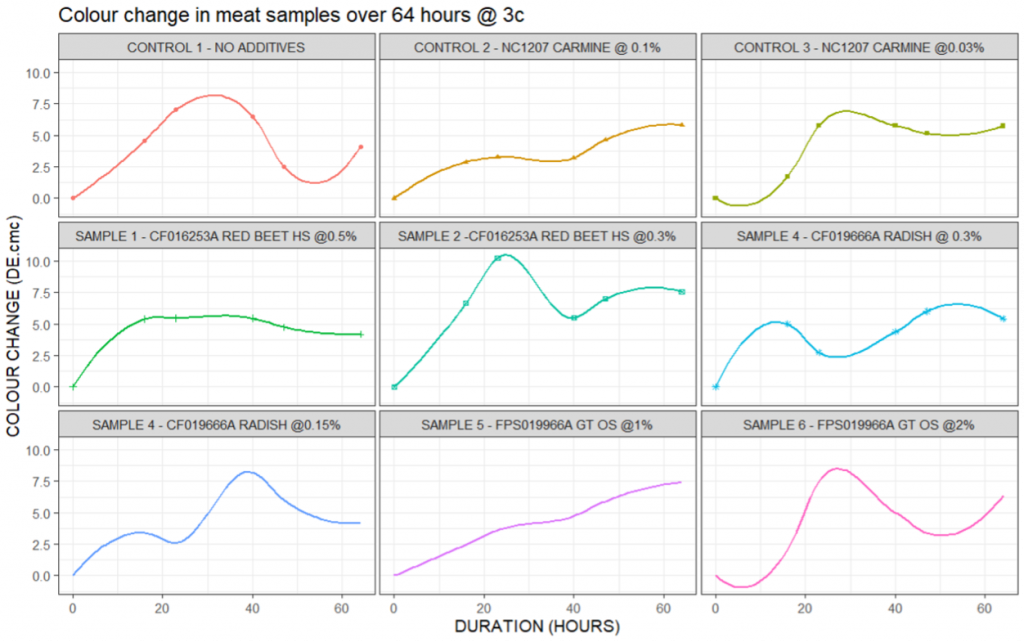

RESULTS –VISUAL ANALYSIS

The visual analysis shows the prepared meat samples at the start of the study, Control 1 had already begun to oxidize due to high-temperature conditions, this however gives an excellent indication of the importance of dosing colours and antioxidants in these types of applications to prolong visual freshness indicators.

Results are shown 16 hours into the investigation:

Some samples have taken on a more natural meat pigment colour through degradation. When comparing the samples against the control samples, all appear to have a much more “consumer” friendly colour.

Control 2 gives an example that carmine when dosed at too high a dosage will not provide a natural “meat” colour. Control 3shows a much more natural meat colour.

Samples 1, 2, 3 & 4, are all showing excellent “meat colour” replication.

Samples 5 & 6 are showing good oxidation inhibition compared to Control 1.

At 23 hours

Samples at 23 hours are starting to show degradation of colour, however when comparing all samples against the Control1sample, all look to have a more attractive colour than this sample.

Samples 1 & 3appear to provide a much more natural meat colour and at this point in the investigation could be considered suitable replacements for carmine.

Sample 5 isstillshowingsomegoodinhibitionofoxidationwhichifpairedwithSample 1 & 3could prevent further colour change.

At 40 hours:

At 40 hours the samples are showing strong signs of colour change, Control 2has not faded as much due to it being a relatively strong dose of carmine.

Samples 1 & 2 are showing good signs of stability and a more natural meat colour is prominent.

Sample 5 is showing good inhibition of rancidity as is Sample 6.

At 47 hours:

At 47 hours Samples 2,3,4 & 6are showing instability, Control samples are also beginning to differ.

At 64 hours:

At 64 hours Samples 5&6are starting to show strong signs of oxidation, Samples 4 & 2are beginning to fade out as are Control 2 & 3 which are darkening due to oxidation. Sample 1 shows good colour retention and stability.

Results:

The visual analysis shows the gradual colour change of the samples over 64 hours when stored chilled at 3oC.

The most stable sample is Sample 1, this shows excellent stability in processed meat applications when dosed at 0.5%.

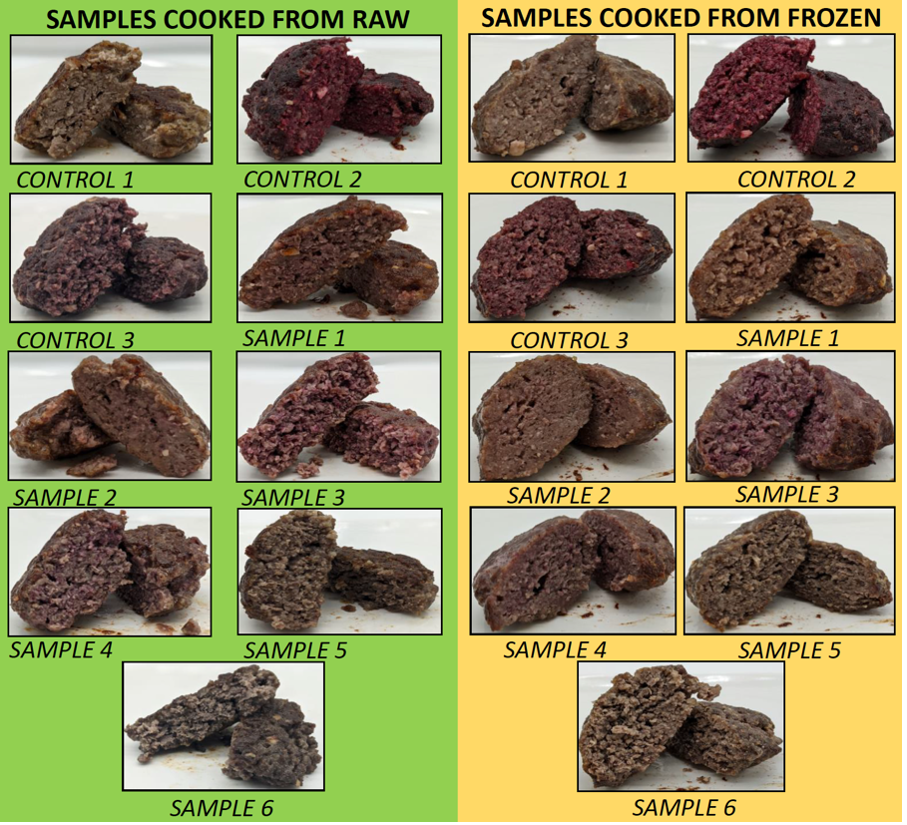

VISUAL ANALYSIS: COOKED PRODUCT

The samples were cooked from raw and from frozen to determine if there are any impacts of

preservation or cooking on the patties dosed with colour in a real-world application.

RESULTS -X-RITE GRAPHS

The samples are shown in each graph and show the colour stability of each sample. Sample 1 has shown excellent stability as has Sample 5 which depicts the stability of the meat pigments when dosed with an antioxidant.

CONCLUSION/ FINDINGS

The study examined several colour products dosed into mincemeat and formed into burgers with typical co ingredients as found in a supermarket. Of the colours examined it was found that CF016253A Red Beet HS dosed at 0.5% provided the best stability whilst providing an attractive “fresh” minced meat colour. This was compared with a control sample that depigmented rapidly after being made. FPS019966A GT OS dosed at 1% provided strong inhibition of rancidity throughout the duration of the study, and only towards the final hours did signs of oxidation appear.

Due to the nature of the application material (minced beef) degrading rapidly, it would be wise to suggest that a combination of GT OS and Red Beet HS are used in processed meat products. The GT OS will provide sufficient inhibition of rancidity preventing the material from darkening/lightening, whilst the Red Beet HS will provide a long-standing natural and fresh colour throughout.

This study has been done by Plant-Ex’s department of Food Protection Systems, for more details about the products used in this study email us at sales@plant-ex

For more information about meat applications, check out our blog post for more information on antioxidants and preservatives best suited for meat applications here: FPS Meat Application Blog