‘Matching’ is a free of charge service offered by Plant-Ex, and is very popular amongst new and existing customers. Often, this service is popular as we can offer more competitive pricing in comparison to other flavour houses, without affecting the quality of the flavour or altering the end product in any way.

You may be sceptical about how we can replicate the flavour exactly… there is a lot of science behind the process, paired with the level of experience of our flavourists. Read on to find out more about the matching process!

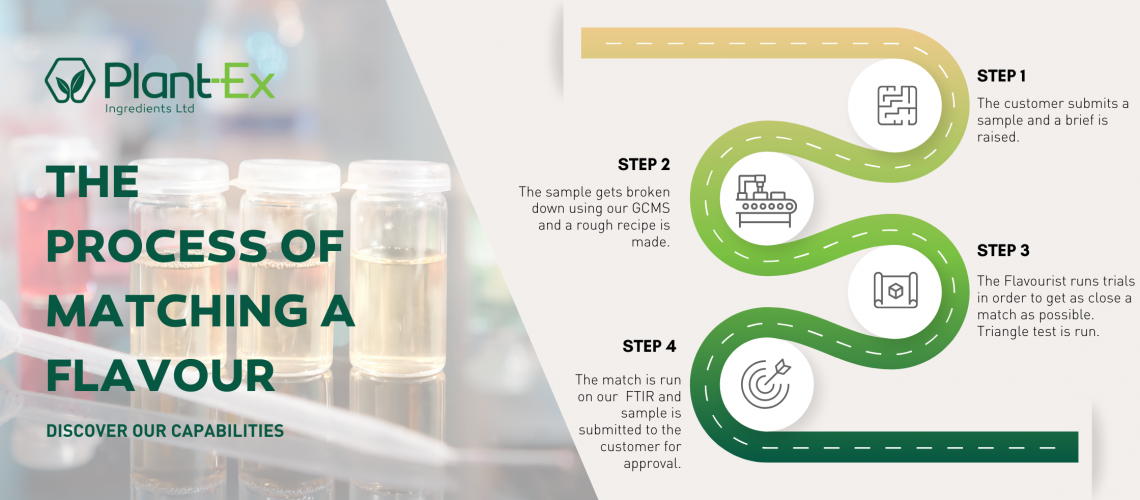

Step 1:

Firstly, we require the customer to send us a small sample that they’d like us to match – this is for analysis work. Typically, we’d require anything from 10g, and it doesn’t matter whether this is a liquid or a powder.

Alongside the sample, we’d need a copy of the spec and a rough target price. Some customers are unable to share complete specs for confidentiality reasons. In circumstances like these, we’d simply require a snippet of the ingredients to indicate what carrier we should be using, as well as if there are any ingredients such as yeast extract or colouring.

Internally, a brief is then raised by the customer’s account manager, which gets allocated to one of our flavourists.

Step 2:

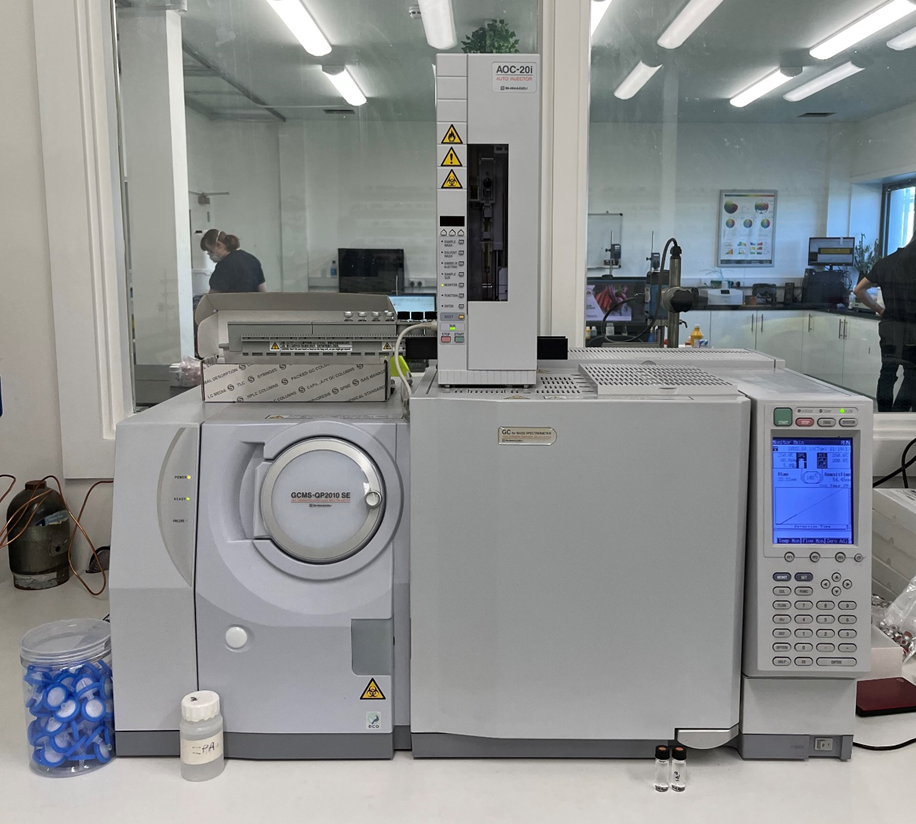

The sample sent in by the customer is injected into our Gas Chromatography-Mass Spectrometry, or GCMS for short. Inside the GCMS, there are lots of coils which ‘pull apart’ the flavour and break it down into what aroma chemicals are present. This process takes up to 2 hours to analyse the flavour.

Recently, we have also installed an autosampler – this is the box at the top of the GCMS. The purpose of this is so that samples can be uploaded throughout the day and overnight, meaning the flavourists don’t need to spend as much time loading the samples on, and therefore more flavours can be matched per week. We’re all about productivity at Plant-Ex!

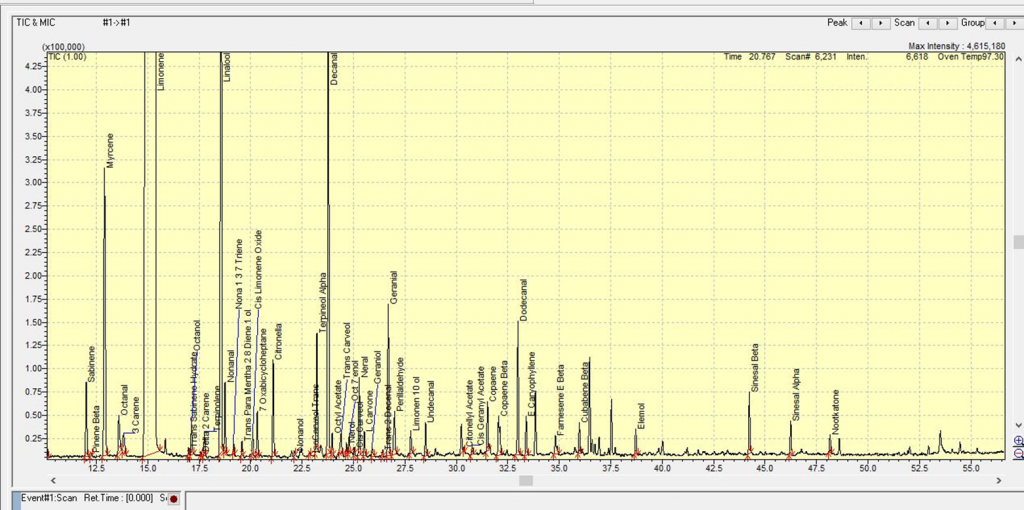

Once the sample has been fully run through the GCMS, a graph such as the following is given:

This example of the GCMS graph is the results from an orange flavour. Each peak represents a different molecule, which corresponds to an aroma chemical. The height of the peak determines the strength and dose of that aroma chemical, too.

The graph gets analysed by the flavourists, who may group certain peaks together and replace them with essential oils. Additionally, some peaks may be present on the graph which don’t make sense – this is when there is still some residue within the coils. The flavourists can recognise this, and remove the peak.

Based on the recipe above, the flavourists create a ‘new’ recipe, which gets re-run on the GCMS, and a new recipe guide is given.

Step 3:

The flavourists will then organoleptically test the new recipe, tweaking it slightly with the levels of aroma chemicals in order to get the correct balance, and a close match. This is where the real magic happens! For example, if a raw material is being used at 0.01% too high, it may totally alter the profile of the flavour.

There can be up to 20 trials before the balance is done right, however typically it only takes up to 5 for our flavourists.

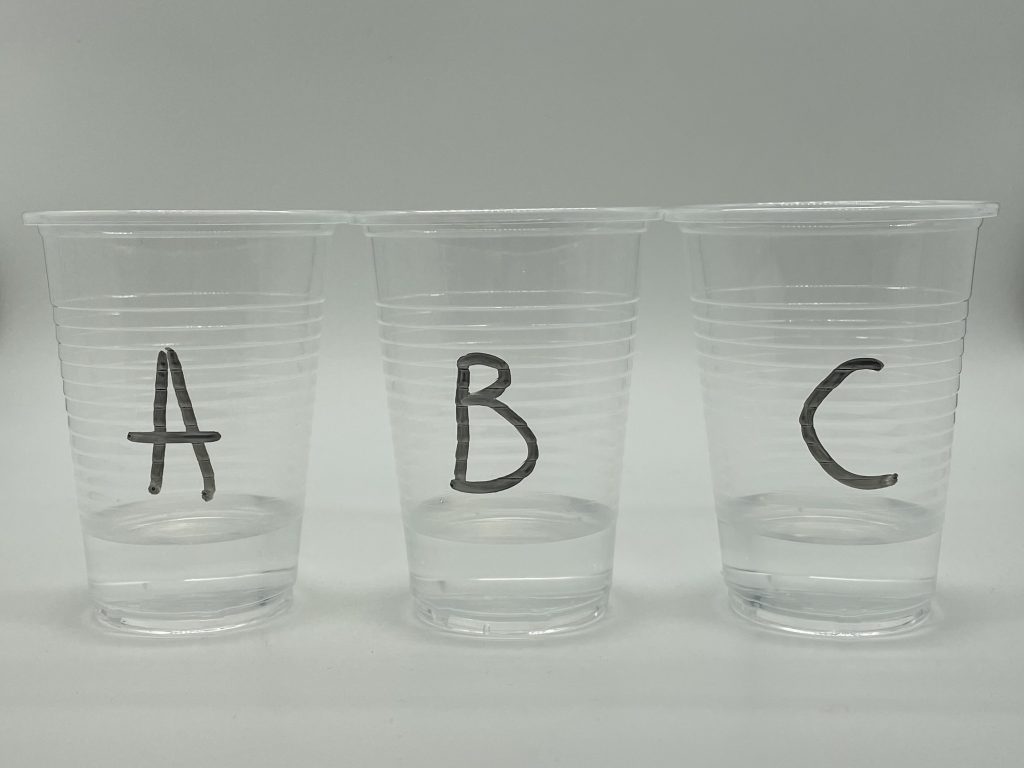

Once the flavourist in charge of the brief is satisfied that their match is exact, they will gather a tasting panel and run a triangle test.

- Each person on the tasting panel gets given 3 small cups of solution (0.1% of flavour in 99.9% water). The cups are labelled A, B and C.

- The participant has to smell and taste each cup to try and determine which two samples are the same, and which one is different. Each participant in the triangle test has different results – e.g. Person 1 may have A and B as the target flavour and C as the match, whereas person 2 may have A and C as the match and B as the target flavour. This is done so that they cannot compare answers and sway each other.

- The results of the triangle test are gathered, and ideally everyone on the tasting panel gets the answer wrong, because the more people who cannot pinpoint the different flavour the better as it demonstrates the match was so close you couldn’t tell a difference.

Step 4:

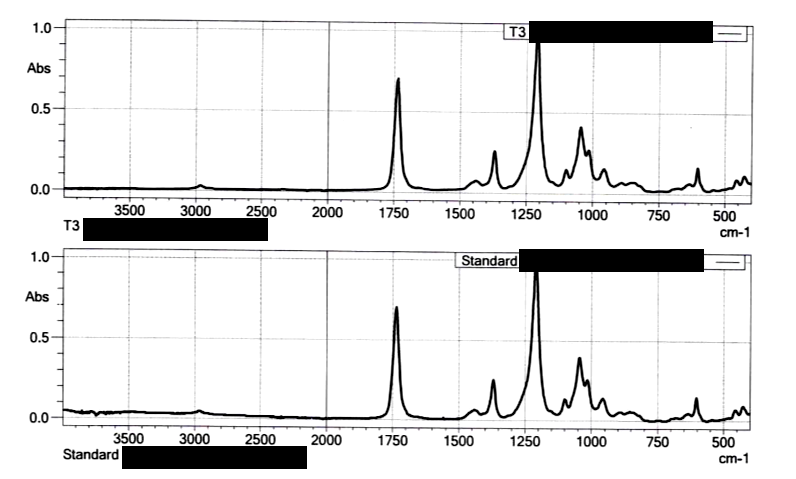

Once we have an 85% plus success rate in the triangle test, the target sample (named ‘standard’ gets run on our FTIR against the trial, and 2 graphs get given (like the following):

The above graph is results of a watermelon flavour standard (bottom graph) versus the trial (top graph). As you can see, the trial and the standard have very similarly shaped graphs, demonstrating how close a match they are.

The FTIR also gives a score out of 1000. Plant-Ex consider everything over 970 to be a match, as it means the difference is so minor that organoleptically, it cannot be picked up. The score for the above watermelon flavour was 975, and the customer ended up approving this trial and now is the product they order from us – not only being provided with a better service and shorter lead times, but we provided them with a significant cost saving!

After the FTIR test has been run, we run one final test to ensure everyone is happy – an applications test. The purpose of this is to ensure that the flavours react the same way and no volatiles change or burn off in application. Changes may occur in flavours depending on cooking temperatures, pH and mixed with other ingredients.

Interested in getting your flavours matched for a faster, more flexible service and more competitive pricing? Get in touch today: sales@plant-ex.com

Struggling to think of a flavour? Check out our applications page for inspiration of where to use Plant-Ex flavous in your products.