Burnt Sugar is a caramelised sugar syrup produced through the controlled heating of food sugars without the addition of other ingredients/additives. The Maillard reaction caramelised the starches contained in sugar and produces the brown colour and caramel flavour.

Plant-Ex offers a large range of caramels that can be used for multiple applications serving different purposes. Here are some of our top options:

Burnt Sugar (or E150a) has very good heat and light stability and is available in liquid and powder form. It can be used in a wide range of sweet and savoury applications and is considered a colouring food ingredient when used for its flavour and colour. When used just for its colour, it is declared as a colour under the E-number E150a.

Plant-Ex Caramel Portfolio:

| Product Code | Name | Description | Strength/Colour Units (EBC) | Format | Class type | Solubility | Label declaration |

| NC0020/CF0020 | Burnt Sugar Syrup | A dark brown viscous liquid produced through the controlled heating of glucose syrup, without the addition of chemical additives | 14,000 – 16,000 EBC | Liquid/Syrup | Class I | Water | Colour: E150a or Plain Caramel, or Natural Flavouring, or Burnt Sugar (Colouring Foodstuff) |

| NC0021/CF0021 | Burnt Sugar Powder | A brown powder produced through controlled heating of Glucose Syrup, without chemical additives, and spray dried into a powder | 16,000 – 20,000 EBC | Powder | Class I | Water | Colour: E150a or Plain Caramel, or Natural Flavouring, or Burnt Sugar (Colouring Foodstuff) |

| NC015435A | Plain Caramel Powder | A brown powder produced through controlled heating of Glyucose Syrup, without chemical additives spray dried onto Wheat derived Maltodextrin | 18,000 – 19,4000 EBC | Powder | Class I | Water | Colour: E150a or Plain Caramel, or Natural Flavouring, or Burnt Sugar (Colouring Foodstuff) |

| CF019097A | Burnt Sugar Powder 2X | Dark brown powder, obtained by the controlled heat treatment of food sugars in presence of alkaline compounds and dried via spray drying onto maltodextrin | 30,000 EBC | Powder | Class I | Water | Colour: 150a or Plain Caramel, or Natural Flavouring, or Burnt Sugar (Colouring Foodstuff) |

| NC1501 | Caramel Colour | Amber, Class III, beer stable, water soluble liquid with a positive colloidal charge used to colour food and beverage products | 39,000 – 43,000 EBC | Liquid/Syrup | Class III | Water | Colour: E150c or Ammonia Caramel |

| NC1506 | Caramel Powder | Dark brown, Class III, water soluble powder with a positive colloidal charge used to colour food and beverage products | 47,000 – 53,000 EBC | Powder | Class III | Water | Colour: E150c or Ammonia Caramel |

| NC2107 | Caramel Extract | Dark brown, Class IV, double strength, acid proof, water soluble liquid with a negative colloidal charge used to colour food and beverage products | 46,000 – 47,5000 EBC | Liquid/Syrup | Class IV | Water | Colour: E150d or Ammonia Sulphite Caramel |

| NC012554A | Caramel Powder | Dark brown, Class IV, double strength, acid proof, water soluble powder with a negative colloidal charge used to colour food and beverage products | 78,000 – 90,000 EBC | Powder | Class IV | Water | Colour: E150d or Ammonia Sulphite Caramel |

| NC019781A | Caramel Powder | Dark brown powder, acid stable, obtained by the controlled heat treatment on glucose, in the presence of ammonium sulphite and dried by atomisation. | 95,000 EBC | Powder | Class IV | Water | Colour: E150d or Ammonia Sulphite Caramel |

| NC019782A | Caramel Colour | A dark brown liquid obtained by the controlled heat treatment of glucose in presence of ammonium sulphite. This caramel is a “Double Strength Acid Proof Caramel”. The sulphite gives it a negative colloidal charge and the presence of amine functions allows its stability in acidic medium. | 50,000 EBC | liquid | Class IV | water | Colour: E150d or Ammonia Sulphite Caramel |

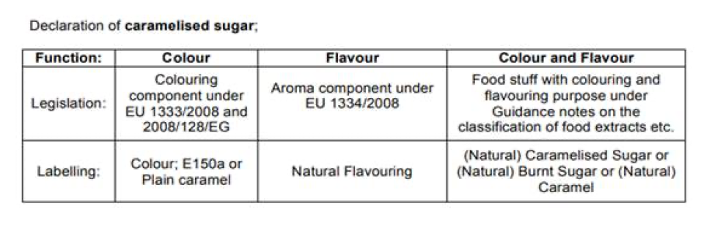

Label Declaration:

Declarations of caramelised sugars as either caramel, flavouring and colouring foodstuff or aroma depends on the primary reason for use.

1. If colouring is the sole reason, the product falls under the food additives regulation EU 1333/2008 and needs to comply with definitions and purity as described in EU directive 2008/128/EG.

2. If flavour is the main reason for use, the product can be seen as an aromatic preparation and then falls under the EU regulation for aroma’s EU 1334/2008. The declaration is then natural flavouring.

The most common declaration however is as such, naming the ingredient “caramelised sugar” or “caramel” which supplies both colour and flavour.

EU Labelling declaration: Colour: E150a, Natural Flavouring, Burnt Sugar.

MORE ABOUT CARAMELS:

For more intense, darker shades of brown, it is possible to use Caramel colours produced from food sugars and reacted with various stabilising ingredients. This will enhance the colour intensity and stability. This process means these Caramels are not clean label and must be declared with an E-number or as a colour additive.

– Ammonia Caramel E150c is used for a brown-yellow colour and is ideally suited for use in Beers, drinks, and sauces.

– Sulphite Ammonia Caramel E150d is the darkest Caramel. It has good acid stability so is primarily used in Soft drinks, confectionary and pet food applications.

Have a sweet tooth? Check our Ultimate Chocolate Guide

Applications:

Each caramel serves a different application, here’s what our technical team recommends:

- E150a: include alcoholic beverages, bakery, sauces, confectionery, dairy and ice cream, pet food, tea, coffee, meat and meat substitutes. Good for general use in multiple applications.

- E150c: used in Beers, sauces, teas, coffee, bakery and savoury applications.

- E150d: acid stable so suitable for acidic applications such as soft drinks and confectionery.

- Colour variation:

- E150a/Burnt Sugar: range in colour shade from light yellow/golden-brown to reddish-brown.

- E150c: Light brown to dark yellow-brown.

- E150d: Darkest brown shade out of all the Caramels, from light brown to dark red/blackish-brown shades like Cola

Want to know where else to use Plant-Ex products? Check out our Applications page for inspiration.

Our team is ready to help you choose the right colour, and dosage for your product. We are also able to provide in-house application trials in our application kitchen. Should you require further details, please email us at sales@plant-ex.com