This article is available as a more in-depth brochure available by contacting sales@plant-ex.com

PLANT- EX FOOD PROTECTION SYSTEMS

We aim to create natural antioxidants and preservatives that provide mostly clean label solutions for use in the food and beverages industry.

-Able to source and supply products internationally, with ease, from trusted suppliers.

-A wide range of technical expertise to support our customers from development through to final application.

-A growing comprehensive FPS portfolio.

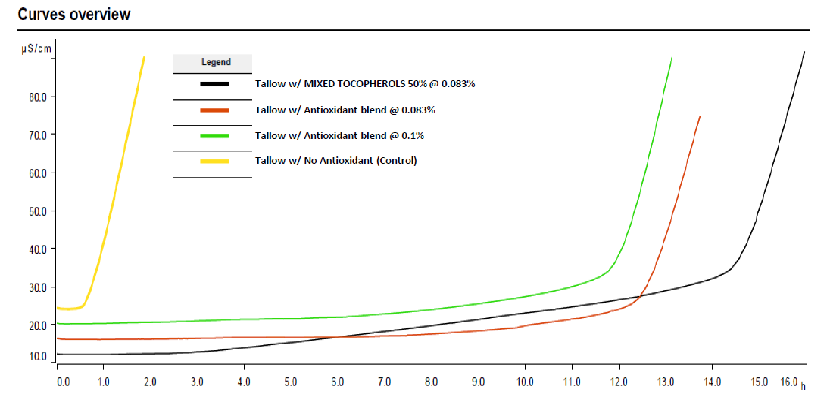

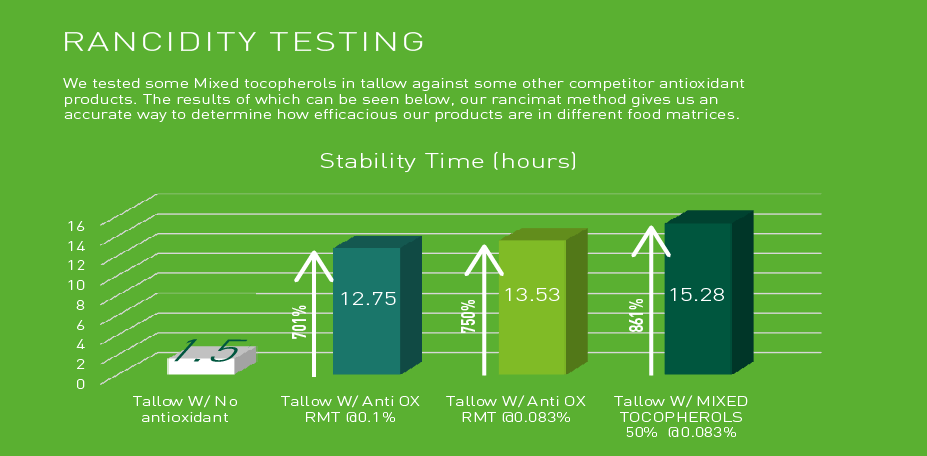

-Rancidity laboratory to highlight the efficacy of our work.

LIPID OXIDATION

Lipid oxidation is a highly complex set of free radical reactions that occur between fatty acids and oxygen, and this results in the oxidative degradation of lipids, which is also known as rancidity.

Lipid oxidation or rancidity means that hydroperoxides have been formed.

Hydroperoxides, through the splitting of fatty acid chains, polymers and dimers, form by-products such as epoxides, alcohols, aldehydes, and ketones.

These by-products interact negatively with proteins, sugars, pigments and even vitamins, causing a range of quality issues with the food product such as off flavours, bad aromas, colour loss, and nutritional deficits.

The two main types of oxidation associated with rancidity in foods are – auto-oxidation and photo-oxidation.

Types of Oxidation

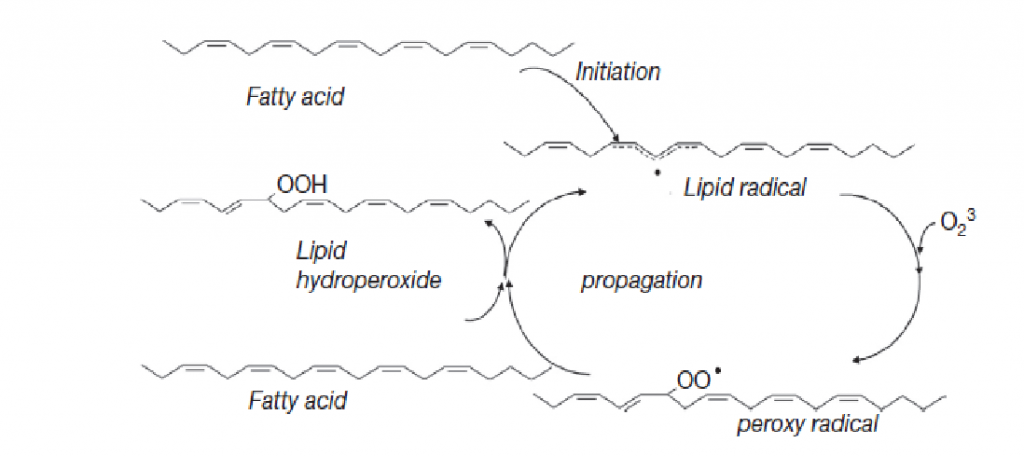

Auto-oxidation takes place over three stages:

• Initiation – A hydrogen atom is abstracted in the presence of initiators such as light, heat, metals or oxygen. This forms a lipid radical, which reacts with oxygen making a lipid peroxide radical.

• Propagation – The peroxide radical reacts with a second lipid which creates a lipid radical. A hydroxy peroxide, the lipid radical formed, then propagates the chain of autooxidation, forming a new reaction in the cycle.

• Termination – Antioxidants may terminate or block the propagating cycle by effectively ending or blocking the hydroperoxide formation, thus delaying the onset of rancidity.

Photo-oxidation is the same as autooxidation but begins when nonreactive triplet oxygen (3O2) is converted to reactive singlet oxygen (O2) through the exposure of UV light radiation.

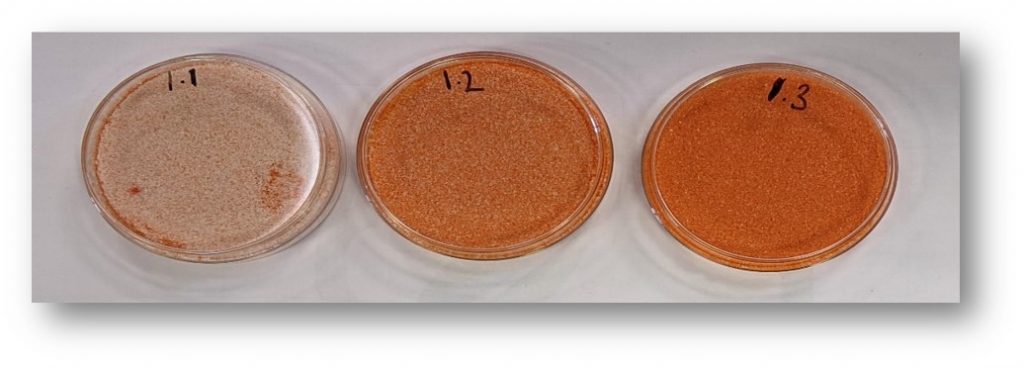

Here we see an example of photo-oxidation in one of our paprika products spread onto salt after 4 days of exposure to constant light.

• Sample 1.1 contains no antioxidant

• Sample 1.2 contains antioxidant at a 1% dosage.

• Sample 1.3 contains antioxidant at a 2% dosage.

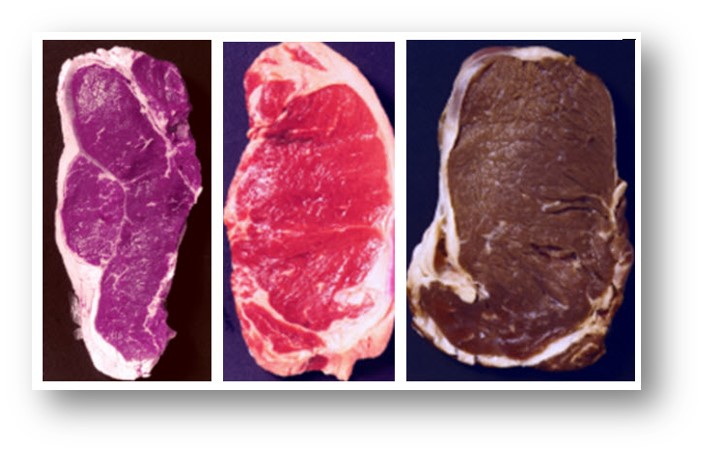

OXIDATION IN MEAT PRODUCTS

Note how the oxidized meat is darker in colour, almost giving the illusion that it is cooked. Visual indicators are the first thing a customer judges the quality of food with, so maintaining a fresh, raw, pink or red colour is key when adding antioxidants to meat products.

Natural Antioxidants – the benefits

There are many benefits for both the producer and consumer when it comes to natural antioxidants:

• Clean Label/Label friendly solutions – on-trend for customers that want to move away from synthetics and be more transparent to their consumer base.

• Multiple applications (each antioxidant performs differently, allowing more choice to combat rancidity).

• No chemicals with nasty side effects.

• No health risks to usage, allowing them permittance worldwide.

• Heat stable options meaning they can withstand high temperatures associated with food processing and cooking oils.

Natural Antioxidants – Plant- Ex portfolio

We have a range of antioxidants suited for meat applications; some of our most popular products that inhibit oxidation in meat are available by sending an email to sales@plant-ex

Microbial Growth and Food Spoilage

Food Safety is at the forefront of any food manufacturing business. Microbial growth and spoilage organisms are one of the biggest concerns.

- Meat products are particularly sensitive to contamination and provide the ideal conditions for microbial growth and foodborne pathogens.

- Microbial growth changes the characteristics of meat products. This is called food spoilage.

- Foodborne pathogens can cause disease and illness, and sometimes this can lead to death.

- All aspects of the meat industry should look to reduce the risk of microbial growth

wherever possible.

Food spoilage organisms cause foods to be unsuitable for consumption. These organisms are classified as:

YEASTS: Ferment sugars produce CO2 and Alcohols, which impact the characteristics of food.

MOULDS: Biodegrade/rot natural materials and foods.

BACTERIA AND FOODBORNE PATHOGENS: Foodborne pathogens are viruses and bacteria such as Salmonella, E. coli, Staphylococcus and Listeria monocytogenes. These pathogens can be extremely harmful to health.

Using pH in meat products to inhibit microbial growth

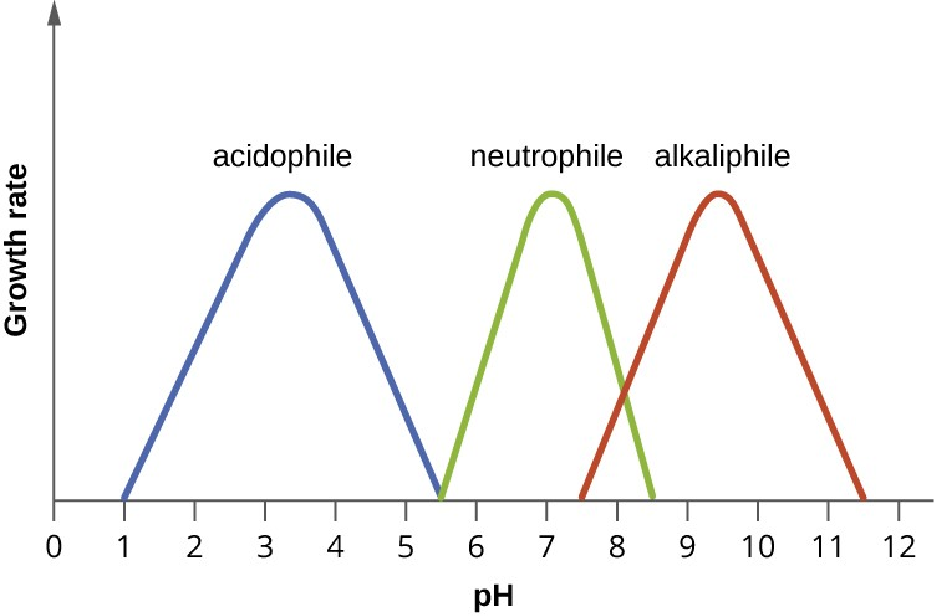

Food spoilage organisms can be split into three main groups: Acidophiles, Neutrophiles and Alkaliphiles.

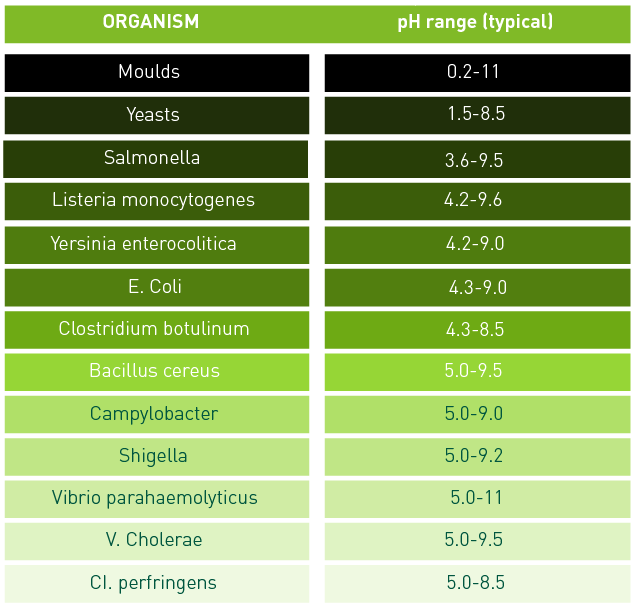

Food spoilage bacteria and foodborne pathogens

Food spoilage organisms’ and food borne pathogens function and thrive in different pH ranges.

Natural Antimicrobials – Plant- Ex portfolio

Our natural antimicrobials suited for meat applications, some of our most popular products that inhibit oxidation in meat are available in our brochure that you can get by contacting sales@plant-ex.com

Synergistic blends – Plant-Ex portfolio

We also provide several synergistic blends that combine our antioxidant and antimicrobial ingredients for an effective method of combating rancidity and microbial growth at the same time. The portfolio is ever-growing, and custom tailor-made products can also be requested. We will work with our customers to achieve the best results possible, providing the most effective means to achieve quality, safe, efficacious outcomes.

Oxidation efficacy laboratory

To get Plant-Ex’s Food Protection Systems or know more about them, please contact sales@plant-ex.com